Filtration efficiency is key to maintaining the profitability and operability of an industrial plant. The accumulation of particles and debris in fluids can cause clogs in pumps, heat exchangers, and hydraulic systems, leading to higher maintenance costs, reduced equipment lifespan, and potential production downtimes.

In this article, we examine how Airpel and Cleanova strainers, including simple, duplex (OV, OW), and self-cleaning models, can optimize filtration processes across various industries and how to choose the best system based on each plant’s specific needs.

The Importance of Efficient Filtration

Using an inadequate filtration system can lead to blockages in cooling systems, reducing thermal efficiency and increasing energy consumption. In hydraulic sectors, contamination of oil emulsions can cause pump and motor damage, shortening their lifespan. In steel processes, slag and metal particles not only affect product quality but also accelerate equipment wear. Meanwhile, in industrial water treatment, pipe blockages result in system failures and higher maintenance costs. All these issues can be mitigated with a robust and efficient filtration system like Airpel and Cleanova strainers.

Airpel and Cleanova Strainer Range

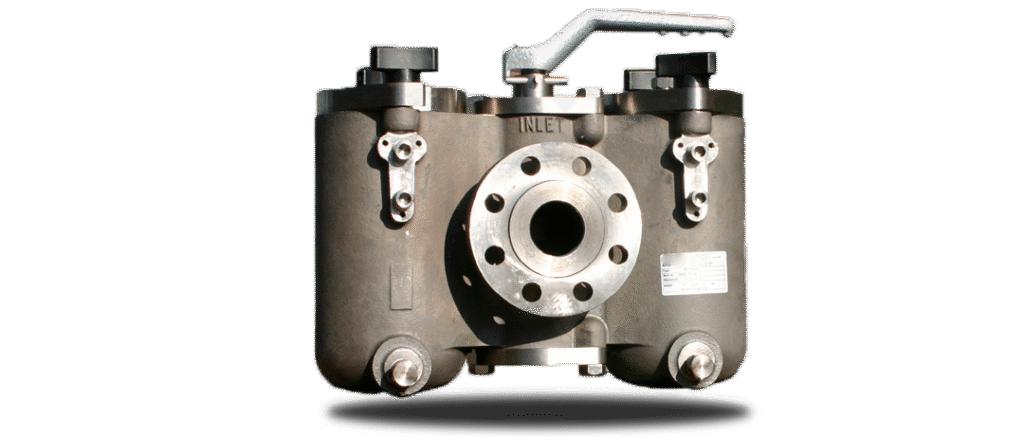

Basket strainers are devices designed to remove unwanted particles from industrial fluids. Depending on the application, they can filter particles from as fine as 10 microns to 6.35 mm.

Simple and Duplex Strainers (OV, OW)

These models are ideal for processes requiring periodic maintenance without halting production. Simple strainers are suitable where planned shutdowns allow filter replacement. For continuous flow processes, duplex strainers (OW) are more versatile—they feature two filtering chambers, allowing element changes without interrupting operation.

📌 Applications: Cooling systems, lubricant filtration, chemical and petrochemical processes.

Self-Cleaning Strainers

Airpel self-cleaning strainers provide continuous filtration without manual intervention. Unlike traditional filters, these models automatically discharge accumulated debris, lowering operating costs and preventing unplanned shutdowns. They are ideal for fluids with high particulate loads and operations requiring maximum efficiency and reliability.

📌 Applications: Pulp and paper industry, mining, wastewater treatment, food and beverage processing.

How to Choose the Right Strainer

Choosing the right filtration system requires assessing the fluid’s characteristics, particle size and type, and operational conditions like pressure and temperature. A strainer designed for low-pressure applications won’t perform well under high-demand conditions. Maintenance frequency is also crucial—self-cleaning models are better suited for processes where manual intervention should be minimized. Finally, material compatibility ensures durability and avoids premature corrosion or degradation.

Maintenance Tips for Basket Strainers

Proper maintenance is key to extending equipment lifespan and ensuring optimal performance. Regularly inspect and clean the filtering screens to prevent build-up that reduces system efficiency. In simple and duplex models, plan for scheduled replacement or cleaning of baskets (typically stainless steel SS316), depending on fluid contamination levels.

Monitor pressure differentials to detect early saturation or partial blockages. Always use original replacement parts to ensure system compatibility and prevent unexpected failures.

Complementary Brands in the Cleanova Range

Besides Airpel, Cleanova includes specialized fluid and gas filtration solutions from brands like Dollinger, Plenty, and Vokes. These lines offer advanced technology for high-efficiency separation and particle reduction.

Dollinger: Air and gas filtration in compression systems.

Plenty: High-performance filters for pipelines and chemical processes.

Vokes: Filtration solutions designed to protect rotating equipment and control environmental contamination.

Conclusion

Choosing the right strainer is a strategic decision that directly impacts a plant’s operational efficiency and maintenance costs. Airpel and Cleanova strainers offer top-tier solutions that adapt to each need. Optimizing filtration systems not only extends equipment life but also improves product quality and reduces environmental impact.

If you need expert guidance to find the best solution for your company, our team at Sistemiza is ready to help.

📢 Get in touch and optimize your filtration process today!